Improving the Livelihoods of Smallholder Farmers in Dadeldhura

Littri Gaun is a characteristic remote, hilly village in Dadeldhura district of Nepal. Relatively low agricultural yields, soil erosion and labor out-migration are major challenges for monsoon-dependent agriculture in this region. During the kharif season, farmers mostly grow the dominant staple crops – unbunded upland rice and maize. Some farmers also practice maize-soybean mixed cropping because soybean fetches a good price in the market. Finger millet is also grown for home consumption in some areas during kharif.

Littri Gaun is a characteristic remote, hilly village in Dadeldhura district of Nepal. Relatively low agricultural yields, soil erosion and labor out-migration are major challenges for monsoon-dependent agriculture in this region. During the kharif season, farmers mostly grow the dominant staple crops – unbunded upland rice and maize. Some farmers also practice maize-soybean mixed cropping because soybean fetches a good price in the market. Finger millet is also grown for home consumption in some areas during kharif.

Farmers in Littri Gaun believe that chemical fertilizer can destroy soil, and use only farmyard manure and plant litter to enrich their soil. Low nutrient levels — particularly for Nitrogen – have led to consistently low crop productivity. Moreover, farmers grow traditional local varieties for which seeds may have been saved for several years, as seed replacement rates are low. With men migrating outside for work, women are left responsible for the agricultural production, as well as household duties, resulting in high levels of drudgery for women and high labor constraints during peak agricultural times.

The Cereal Systems Initiative for South Asia in Nepal (CSISA-NP) began working with farmers in Littri Gaun in 2012 and facilitated farmers in the village to form a group called “Ugratara Agriculture Group.” CSISA works with Ugratara to introduce new, suitable crop varieties, better-bet agronomic practices and small-scale machinery that women can use.

CSISA and Ugratara have conducted several maize trials to screen and grow different registered hybrids, to evaluate different crop establishment methods and to experiment with different methods of fertilizer management. Trials showed that hybrid maize yields were more than double to those of the local varieties under the same management conditions. With hybrids, Ugratara has even harvested up to three times the yield of the local maize varieties. Among the genotypes tested, group members preferred Kanchan-101 (hybrid) because of the high and early yields. Trials also showed that the local maize variety produced higher yields when fertilizer was applied, demonstrating the importance of good nutrient management.

During a farmers’ field day Ugratara group members expressed that improved varieties, like the maize variety Kanchan 101 (hybrid) introduced by CSISA, are more productive than their local maize. Ugratara group member, Naresh Khadka said, “We are producing more than double using the hybrid Kanchan-101 and it’s ready early than the local variety.” For upland rice, trials also showed that the appropriate use of chemical fertilizers nearly doubled yields of local rice varieties and that chemical fertilizer increased yields over those achieved through the application of farmyard manure.

During a farmers’ field day Ugratara group members expressed that improved varieties, like the maize variety Kanchan 101 (hybrid) introduced by CSISA, are more productive than their local maize. Ugratara group member, Naresh Khadka said, “We are producing more than double using the hybrid Kanchan-101 and it’s ready early than the local variety.” For upland rice, trials also showed that the appropriate use of chemical fertilizers nearly doubled yields of local rice varieties and that chemical fertilizer increased yields over those achieved through the application of farmyard manure.

CSISA also introduced improved varieties of lentil, which has increased the number of farmers producing lentil, lentil yields, and household lentil consumption. Farmers have also been able to sell their surplus lentil production in the market for NRs. 150/kg. “After seeing the benefits of improved lentil variety, more farmers are now expanding their area under lentil cultivation,” said Khadka.

Finally, CSISA introduced small machines like the mini tiller and the jab planter, which helped women to prepare and cultivate land, making them more self-sufficient, saving their time and helping them to adapt better to labor shortages. Women in Littri Gaun are not allowed to plough land with bullocks, as it is considered to be men’s work. Saru Khadka, a lady member of Ugratara group, said, “By using minitiller for preparing our fields, we don’t have to depend on men for labor and bullocks.” Participation in Ugratara has helped the group’s women members to feel empowered. Khadka acknowledged that women in Ugratara have learned to confidently express their views and problems to relevant authorities and they feel more capable and assertive now.

This article is authored by A.P. Regmi, Agronomist, CIMMYT.

In India, farmers with large landholdings from prosperous agricultural states like Punjab can often buy expensive and sophisticated machines for their farm operations. However, resource-poor farmers from states such as Bihar and Odisha may not be able to afford the same machines or services and, given that their landholdings may be considerably smaller, may have different needs. Farmers all along the spectrum of landholdings need to be able to access differently priced appropriate machinery based on their specific requirements. Machinery for mechanized threshing is one such example.

In India, farmers with large landholdings from prosperous agricultural states like Punjab can often buy expensive and sophisticated machines for their farm operations. However, resource-poor farmers from states such as Bihar and Odisha may not be able to afford the same machines or services and, given that their landholdings may be considerably smaller, may have different needs. Farmers all along the spectrum of landholdings need to be able to access differently priced appropriate machinery based on their specific requirements. Machinery for mechanized threshing is one such example.

The gap between research and the application of new technologies or management practices on farmers’ fields often results because farmers do not receive timely information about emerging research outputs, technologies or improved practices. Innovative new methods of linking research, products, practices and farming communities must be explored and developed.

The gap between research and the application of new technologies or management practices on farmers’ fields often results because farmers do not receive timely information about emerging research outputs, technologies or improved practices. Innovative new methods of linking research, products, practices and farming communities must be explored and developed.

Mugalodi Ramesha is Irrigated Rice Breeder, IRRI and CSISA Objective 3 Leader. He has more than two decades of experience developing high yielding varieties with better grain quality, resistance to biotic stresses, better adaptability to puddle transplanted and dry direct seeded conditions in South Asia. He has developed and released two rice hybrids and three varieties for different states of India, published more than 60 research papers and been recognized through multiple awards.

In this article, he offers his personal insights on some of the most pressing issues concerning rice breeding today:

Mugalodi Ramesha is Irrigated Rice Breeder, IRRI and CSISA Objective 3 Leader. He has more than two decades of experience developing high yielding varieties with better grain quality, resistance to biotic stresses, better adaptability to puddle transplanted and dry direct seeded conditions in South Asia. He has developed and released two rice hybrids and three varieties for different states of India, published more than 60 research papers and been recognized through multiple awards.

In this article, he offers his personal insights on some of the most pressing issues concerning rice breeding today:

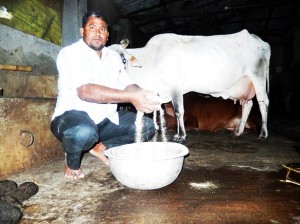

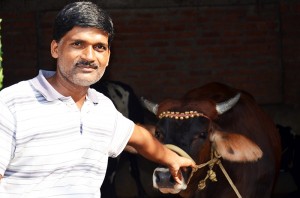

Ram Nandan Prasad, a dairy farmer in Muzaffarpur, Bihar, was convinced that his 19–20 crossbred dairy cattle could yield more milk than they were producing. So, he fed them concentrates available in the local market and ensured high levels of hygiene. Yet, the average yield per cow was just 15–20 liters per day.

Ram Nandan Prasad, a dairy farmer in Muzaffarpur, Bihar, was convinced that his 19–20 crossbred dairy cattle could yield more milk than they were producing. So, he fed them concentrates available in the local market and ensured high levels of hygiene. Yet, the average yield per cow was just 15–20 liters per day. Barsaprasad Hembram, a maize farmer from Mayurbhanj district, Odisha, purchased a variety of modern farm machines this year by participating in a government scheme that gives farmers a 50 percent subsidy on tractors and seven auxiliary implements such as the seed drill. Today, Hembram uses his new farm equipment to provide agricultural custom-hire services to other like-minded farmers, charging $14.35 (Rs. 910) per hour for the tiller and $15.78 (Rs. 1,000) per hour for the Mould Board plow.

Barsaprasad Hembram, a maize farmer from Mayurbhanj district, Odisha, purchased a variety of modern farm machines this year by participating in a government scheme that gives farmers a 50 percent subsidy on tractors and seven auxiliary implements such as the seed drill. Today, Hembram uses his new farm equipment to provide agricultural custom-hire services to other like-minded farmers, charging $14.35 (Rs. 910) per hour for the tiller and $15.78 (Rs. 1,000) per hour for the Mould Board plow. One of the biggest challenges for women farmers in Odisha is to gain recognition as farmers and not just laborers. For most development agencies working in the state’s agriculture sector, the word farmer is synonymous with a man. Women farmers, especially those in the state’s tribal regions, remain unnoticed. Flying under the radar, women miss out on valuable opportunities to use and learn new technologies that can help reduce their drudgery. Besides, most agricultural machines are designed with the assumption that men will be the end users, so even when women access to these machines, they sometimes find the machines cumbersome or unusable. Numerous complementary schemes introduced to benefit farmers also often fail to recognize women’s needs and circumstances; the Kisan Credit Card, for example, is allotted based on land patta (legal record of rights), but women mostly do not have land in their name.

One of the biggest challenges for women farmers in Odisha is to gain recognition as farmers and not just laborers. For most development agencies working in the state’s agriculture sector, the word farmer is synonymous with a man. Women farmers, especially those in the state’s tribal regions, remain unnoticed. Flying under the radar, women miss out on valuable opportunities to use and learn new technologies that can help reduce their drudgery. Besides, most agricultural machines are designed with the assumption that men will be the end users, so even when women access to these machines, they sometimes find the machines cumbersome or unusable. Numerous complementary schemes introduced to benefit farmers also often fail to recognize women’s needs and circumstances; the Kisan Credit Card, for example, is allotted based on land patta (legal record of rights), but women mostly do not have land in their name. Mechanized rice production, including mechanized drill seeding, has the potential to improve yields and reduce labor demand in Tamil Nadu. Because mechanized rice production involves a relatively knowledge-intensive set of practices, extension agents involved in providing support and information must receive proper training. Capacity building efforts for state extension agents are often insufficient and existing training programs sometimes suffer from being either too theoretical or narrowly focused on a small window of the cropping cycle.

Mechanized rice production, including mechanized drill seeding, has the potential to improve yields and reduce labor demand in Tamil Nadu. Because mechanized rice production involves a relatively knowledge-intensive set of practices, extension agents involved in providing support and information must receive proper training. Capacity building efforts for state extension agents are often insufficient and existing training programs sometimes suffer from being either too theoretical or narrowly focused on a small window of the cropping cycle. At present, Laxmi spends most of her time tending to her agricultural fields and livestock and struggles to balance her farm work with the needs of her family. Across the mid-hills, the burden of farm management is falling increasingly on women household members like Laxmi who stay behind. Further, the number of bullocks has declined precipitously, which also delays key farm operations like ploughing. For both reasons, the niche for scale-appropriate mechanization is strong but beyond the reach and current experience of most farmers.

At present, Laxmi spends most of her time tending to her agricultural fields and livestock and struggles to balance her farm work with the needs of her family. Across the mid-hills, the burden of farm management is falling increasingly on women household members like Laxmi who stay behind. Further, the number of bullocks has declined precipitously, which also delays key farm operations like ploughing. For both reasons, the niche for scale-appropriate mechanization is strong but beyond the reach and current experience of most farmers. Invited by the Department of Agriculture Extension (DAE) in May to visit the Go Green Project of Hridoye Maati o Manush Program (soil and men in heart), Ambassador Mozena made use of the occasion to also visit the CSISA-Mechanization and Irrigation (CSISA-MI) project, which is partnered with DAE. At the CSISA-MI project site in Fulbaria village, Ambassador Mozena witnessed a demonstration of one of the newest agri-technologies in Bangladesh – the reaper machine. As part of the CSISA-MI promoted agri-machineries, the reaper allows rapid harvesting and subsequent replanting of the next crop within the recommended planting window. It also allows farmers to save money on labor, the prices of which tend to increase drastically during harvest season, while freeing up time for other activities. In addition to DAEas the public sector partner, CSISA-MI has also partnered with machine manufacturer ACI to import and sell the reaper in Bangladesh.

Invited by the Department of Agriculture Extension (DAE) in May to visit the Go Green Project of Hridoye Maati o Manush Program (soil and men in heart), Ambassador Mozena made use of the occasion to also visit the CSISA-Mechanization and Irrigation (CSISA-MI) project, which is partnered with DAE. At the CSISA-MI project site in Fulbaria village, Ambassador Mozena witnessed a demonstration of one of the newest agri-technologies in Bangladesh – the reaper machine. As part of the CSISA-MI promoted agri-machineries, the reaper allows rapid harvesting and subsequent replanting of the next crop within the recommended planting window. It also allows farmers to save money on labor, the prices of which tend to increase drastically during harvest season, while freeing up time for other activities. In addition to DAEas the public sector partner, CSISA-MI has also partnered with machine manufacturer ACI to import and sell the reaper in Bangladesh.