CSISA in Bangladesh

The third phase of CSISA runs from 2015-2021, and is implemented by the International Maize and Wheat Improvement Center (CIMMYT), International Food Policy Research Institute and International Rice Research Institute, with the backing of a wide range of public and private sector partners in Bangladesh. The project builds on previous efforts convened by CSISA in Bangladesh (Phase I and II activities, the CSISA expansion project in Bangladesh (CSISA-BD), and the Rice Value Chain Project). In its third phase, CSISA provides a strategic overarching framework that guides and supports inter-related projects, while maintaining a focus on scaling-out innovative crop management practices and technologies to smallholder farmers.

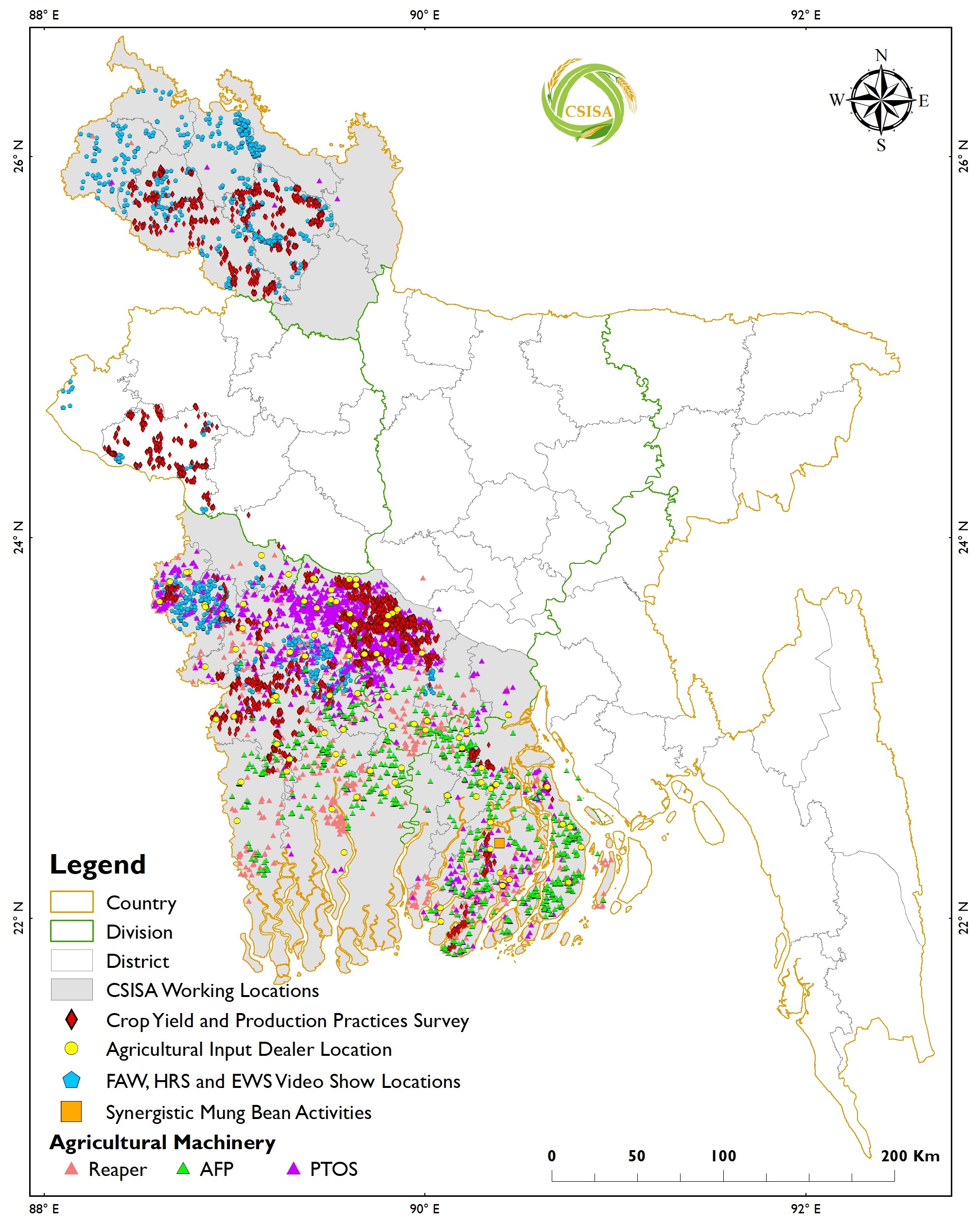

The CSISA project works in Bangladesh’s USAID Feed the Future Zone of Influence (south western Bangladesh) and in Rangpur Division in northern Bangladesh.

In Bangladesh, CSISA Phase III now focuses on applied research on the following topics:

- Directly sown rice to address labor and energy constraints to precision rice establishment

- Agronomic and variety recommendations to reduce the threat of wheat blast

- Increasing the capacity of NARES to conduct participatory science and technology evaluations

- Rice-fallows development in coastal Bangladesh

- Deployment of better-bet agronomic messaging through private sector partners and dealer networks

- Managing risk by coping with climate extremes: Early wheat for combating heat stress

Key achievements include:

- With support from CSISA, the Bangladesh Agricultural Research Institute (BARI) was able to fast-track the release of the breeding line BAW 1260 in late 2017 as ‘BARI Gom 33’. BARI Gom 33 is derived from a CIMMYT cross and is resistant to wheat blast. It is also bio-fortified high Zn content (50-55 ppm) in comparison to other wheat varieties (averaging 40 ppm). BARI Gom 33 can therefore address critical zinc deficiency concerns for pregnant women and children in Bangladesh, as well as mitigate wheat blast risks.

- Farmers in the Feed the Future Zone of Bangladesh tried out labor- and energy-saving directly sown rice on a large-scale for the first time. CSISA’s partnership with the Department of Agricultural Extension resulted in 200 hectares of directly sown rice being sown by farm machinery service providers in four districts. Farmers who directly sowed rice averaged profits over $100 per hectare more than with transplanted rice.

- In addition to the release of BARI Gom 33, CSISA continued to support wheat blast surveillance and monitoring efforts in Bangladesh, and printed and distributed 0.3 million wheat blast awareness raising leaflets that reached farmers in disease affected zones across the country. These leaflets were based on agronomic strategies that can be employed by farmers to mitigate the wheat blast as identified by research conducted with the Bangladesh Agricultural Research Institute.

- Responding to CSISA’s mass media and awareness raising campaigns, farmers established rice on 60,000 hectares using healthier rice seedlings grown with simple but improved agronomic management practices. An additional 28,000 hectares resulted from CSISA’s strategic training of trainers in the Department of Agricultural Extension, who went on to popularize healthy rice seedling techniques among farmers.

- CIMMYT led efforts to improve the production of pulses in the Feed the Future Zone in Bangladesh. By distributing guidelines on better-bet management of mungbean to development partners, the DAE, and the private sector, 3,592 farmers (37% women) on 611 hectares have begun using BARI recommended management practices.

- 14,202 farmers scored dividends averaging $40 per hectare more than for conventional rice varieties by growing fine-grain and aromatic ‘premium quality rice’ varieties on 3,902 hectares in the Feed the Future zone. These farmers achieved higher profits by using CSISA’s advice on how to most efficiently cultivate premium quality rice, as well as through project efforts to assure farmers could sell rice at profits to mills with high demand and fair pricing structures. This was achieved by setting up 25 collection points for mills to directly source rice from farmers throughout the Feed the Future zone.

- CSISA is the only research and development project in Bangladesh actively encouraging farmers to sow their wheat earlier in the calendar year, thereby avoiding risk of crop yield reducing heat stress. Based on this work, and partnerships with DAE, crop monitoring statistics showed that wheat sowing advanced by 10 days on 10%, 9% and 6% of all wheat area in Dinajpur, Jessore, and Faridpur hubs, respectively, in comparison to the previous year. Triangulating these data with farmers in a series of 30 focus group discussions to reliably estimates CSISA contribution to this achievement, sowing was advanced on a total of 4,576 hectares by nearly 14,000 farmers.

- Responding to demand for training in the use of geographic information services (GIS) and spatial analysis from national research partners and students within Bangladesh, CSISA released a book entitled ‘Introduction to basic GIS and spatial analysis using QGIS: Applications in Bangladesh’ provides a set of learning modules introducing young scientists and researchers to GIS and spatial analysis using the open-source QGIS platform, and complementary R, SAGA and GRASS Platforms.

CSISA Mechanization and Irrigation (CSISA-MI)

The Cereal Systems Initiative for South Asia – Mechanization and Irrigation (CSISA–MI) was a five-year project (July 2013–September 2018) funded by USAID, led by the International Maize and Wheat Improvement Center (CIMMYT), working in partnership with iDE Global under the Feed the Future Initiative since 2013. Over six years (including a one-year extension), CSISA-MI transformed agriculture in southern Bangladesh by (1) unlocking potential productivity through irrigation, and (2) the provision of small-scale agricultural machinery and agricultural services. The project developed and trained local agricultural service providers (LSPs)[1], created an entire agricultural mechanization value chain, and scaled out agricultural machinery services across the Feed the Future zone. Farmers received mechanized services from LSPs in the form of axial flow pumps (AFPs), power tiller-operated multi-crop seeders (PTOSs) and harvesters at a reasonable cost and improved productivity. Private sector dealers and manufacturers invested in and introduced the machinery with the technical support of the project.

[1] Local entrepreneurs, facilitated by the project to purchase agricultural equipment and provide affordable mechanization services to farmers.

Intervention Location: 19 districts & 105 upazillas in 3 rural hubs in southern Bangladesh

Service Providers Developed: 3,474 service providers with 3,757 machines (AFP 1,017, PTOS 1,851, and reapers 889)

Land Covered: 135,000 hectares (AFP 34,740 ha, PTOS 84,751 ha, reaper 37,376 ha)

Farmers Reached: More than 308,000 (AFP 47,808, PTOS 223,461, reaper 37,376)

Training Provided: 44,700 farmers, service providers, mechanics, dealers, civil society and Government of Bangladesh officials.

Public Sector Engaged: Bangladesh Agricultural Research Institute (BARI), Department of Agricultural Extension (DAE) and Bangladesh Agricultural Development Corporation.

Investment by Private Sector

CSISA-MI is working to commercialize and catalyze broad availability of agricultural machines for service providers in the Feed the Future zone through partnerships with machinery manufacturers and importers, such as Advanced Chemical Industries, Rangpur Foundry Limited Group, The Metal (Pvt.) Ltd., Chittagong Builders and Janata Engineering. These companies and their service provider clients have invested their own funds to purchase, import, distribute, and market the equipment and the use of machinery services. This has assured available machinery, much of which was imported from abroad, for farmers in the Feed the Future zone. Consequently, US$ 6.9 million has been added to the value of the project.

Other achievements

- Transforming of farmers into service providers as a new business, some of whom have also become machinery dealers

- Developed manufacturers, engineering works, local repair workshops and mechanics

- Raised mechanization awareness along the entire value chain, developed machinery learning villages

- Established spare parts hubs, transformed spare parts shops into machinery dealers

Connecting Service Providers with Micro Finance Institutes

CSISA-MI established linkage between the service providers and micro finance institutes to ensure credit support. CSISA MI in its project life facilitated 228 service providers received US$ 154,436 in credit to buy agricultural machinery. The majority of the credit went to reaper service providers (85), a significant portion of credit was taken by 121 PTOS service providers and a small proportion was used by the 22 AFP service providers. Eight national and local micro finance institutes (ASA, BDS, GJUS, JCF, PBSS, SDC, TMSS and Wave Foundation) provided financial services to the service providers.

Research for Impact

AFP

An improved prototype of AFP was developed in collaboration with local manufacturers, who have also been trained on fabrication, installation, and its efficient operation. A pump test bed was installed at BARI. A booklet was published in Bengali for the service providers to guide the proper installation and safe operation of AFPs. This and related research on surface water irrigation in Bangladesh has been published in an international peer-reviewed journal.

PTOS

CSISA-MI has improved precision of maize seed meters, developed an operators’ calibration key to replace the tedious calibration process, simplified dog clutch design, modified seed metering in brush-type PTOS, developed improved rotary blades to allow strip-till seeding in moist clay soils and implemented numerous minor improvements based on the service providers’ needs. The project has introduced a direct drill maize seeder and fertilizer to increase efficiencies and also developed press wheels for wet soils for 4-wheeled tractor operated zero-till seeder. A “Tillage-and-Seeding Laboratory” has been established at BARI, which allows round the year advanced testing of farm machinery.

Reaper

The 100 cm and 120 cm wide attachable reapers were modified for jute harvesting, especially for wet conditions. Developed sulky wheels to improve ergonomics of the self-propelled reaper operators during road transportation and field operation. Produced and distributed a simple language booklet to service providers on operation, repair and maintenance of reapers.